Additive manufacturing also known as 3-D printing, is changing the speed, cost and flexibility of designing and building future machines...

Additive manufacturing also known as 3-D printing, is changing the speed, cost and flexibility of designing and building future machines for space and earth applications. The manufacturing technique has the potential to improve efficiency and bring down the cost of space launches and other earth applications.

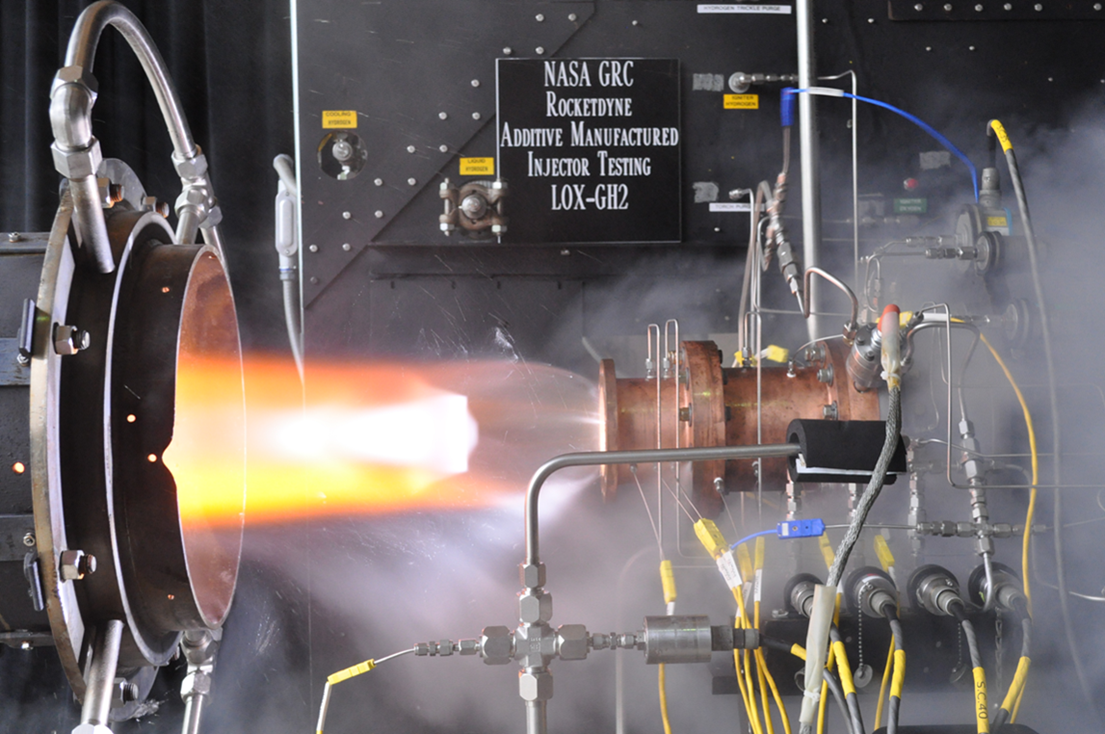

Recently rocket engine maker Aerojet Rocketdyne (AR) in partnership with NASA, successfully completed the first hot-fire tests on an advanced rocket engine thrust chamber assembly 3-D printed using copper alloy materials.

The series of rigorous tests carried out at NASA’s Glenn Research Center, confirmed the 3-D manufactured copper parts could withstand the heat and pressure required by combustion engines used in space launch vehicles for the first time.

The successful hot fire test of subscale engine components paves the way for full scale development.

In all, NASA and AR conducted 19 hot-fire tests on four injector and thrust chamber assembly configurations, exploring various mixture ratios and injector operability points and were deemed fully successful against the planned test program.