U.S. Air Force Life Cycle Management Center's Propulsion Directorate has issued two separate contracts to GE Aviation and Pratt & W...

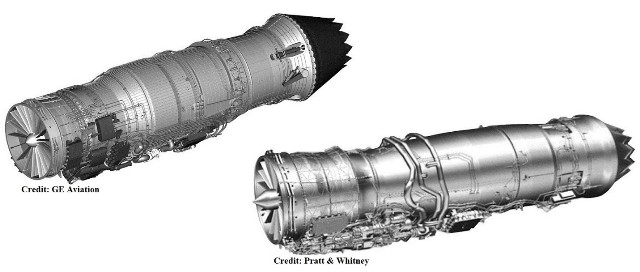

U.S. Air Force Life Cycle Management Center's Propulsion Directorate has issued two separate contracts to GE Aviation and Pratt & Whitney to further mature a sixth generation jet engine under its Adaptive Engine Technology Development (AETD) program.

The contracts were awarded on June 30 and have a total value of $1.010 billion each (including options).

Under the contract, both companies are to design, develop, fabricate, and test complete, flight-weight, centerline, 45,000-pound (200 kN) thrust-class adaptive engines by September 2021 to prove system-level benefits.

The sixth generation adaptive engine optimizes performance and fuel efficiency across the flight envelope by utilizing a third stream of air to optimize the engine at different flight conditions. The engines will demonstrate 25 percent improved fuel efficiency, 10 percent increased thrust, and significantly improved thermal management.

Fixed cycle engines powering today's military aircraft are limited, or "fixed," to one capability: either maximum power or fuel efficiency, which restricts aircraft performance and increases sustainment costs.

The AETP engine differs from fixed cycle engines in its ability to alter from a high-bypass, fuel-efficient engine similar to those deployed on tanker/transport aircraft to a low-bypass, high-performance engine needed for fighter jets. The adaptive feature is combined with an additional source of air, called a "third stream of cooled air," that provides an extra source of air flow to improve propulsive efficiency and lower fuel burn, or to deliver additional air flow through the core for higher thrust and cooling air.

GE's AETP engine design incorporates the industry's most extensive use of advanced manufacturing and heat-resistant material technologies initially developed for GE's commercial jet engines, such as ceramic matrix composites (CMC) and additively manufactured components pioneered on the best-selling LEAP and GE9X engines.

Pratt & Whitney is a world leader in fifth generation engine development, which developed the F119 and F135 engines for the F-22 Raptor and F-35 stealth fighter jets.

In early 2017, the company aims to demonstrate the three-stream technology in an actual engine environment.

Pratt & Whitney's AETD engine will demonstrate advanced turbine blade cooling technologies that allowed the company to achieve the highest-ever turbine temperature in a production-based fighter engine.

Theses engines could power future and legacy combat aircraft operated by US. Air Force.

The contracts were awarded on June 30 and have a total value of $1.010 billion each (including options).

Under the contract, both companies are to design, develop, fabricate, and test complete, flight-weight, centerline, 45,000-pound (200 kN) thrust-class adaptive engines by September 2021 to prove system-level benefits.

The sixth generation adaptive engine optimizes performance and fuel efficiency across the flight envelope by utilizing a third stream of air to optimize the engine at different flight conditions. The engines will demonstrate 25 percent improved fuel efficiency, 10 percent increased thrust, and significantly improved thermal management.

Fixed cycle engines powering today's military aircraft are limited, or "fixed," to one capability: either maximum power or fuel efficiency, which restricts aircraft performance and increases sustainment costs.

The AETP engine differs from fixed cycle engines in its ability to alter from a high-bypass, fuel-efficient engine similar to those deployed on tanker/transport aircraft to a low-bypass, high-performance engine needed for fighter jets. The adaptive feature is combined with an additional source of air, called a "third stream of cooled air," that provides an extra source of air flow to improve propulsive efficiency and lower fuel burn, or to deliver additional air flow through the core for higher thrust and cooling air.

GE's AETP engine design incorporates the industry's most extensive use of advanced manufacturing and heat-resistant material technologies initially developed for GE's commercial jet engines, such as ceramic matrix composites (CMC) and additively manufactured components pioneered on the best-selling LEAP and GE9X engines.

Pratt & Whitney is a world leader in fifth generation engine development, which developed the F119 and F135 engines for the F-22 Raptor and F-35 stealth fighter jets.

In early 2017, the company aims to demonstrate the three-stream technology in an actual engine environment.

Pratt & Whitney's AETD engine will demonstrate advanced turbine blade cooling technologies that allowed the company to achieve the highest-ever turbine temperature in a production-based fighter engine.

Theses engines could power future and legacy combat aircraft operated by US. Air Force.